Researchers Are Investigating Wearable Robots to Expand Job Opportunities

Two teams of researchers are working to remove barriers to the physical challenges of work

“Must be able to lift 50 pounds.”

Physical demands sometimes prevent people from getting the job they want or keeping the job they love, but two teams of Rutgers researchers are working on technology to change that.

In one project, Rutgers faculty are collaborating with engineers at North Carolina State University and New York University to develop a soft, wearable robot. “PECASO” assists workers who have restrictions in upper limb mobility, including people with multiple sclerosis, cerebral palsy, carpal tunnel syndrome, and other illnesses and injuries.

Supported by a $1.9 million grant from the National Science Foundation (NSF), this assistive technology makes it easier to reach, lift, and hold objects. It’s expected to enhance employment opportunities for people with disabilities in the retail, warehouse, and manufacturing sectors.

“The device has evolved throughout the project to become less bulky and intimidating, and more commercial and consumer-friendly,” said Mason Ameri, an associate professor of professional practice at Rutgers Business School.

While the engineers refine the device and integrate AI for more advanced control, the Rutgers team is focused on the HR and policy implications. Douglas Kruse, Lisa Schur, and Hazel-Anne Johnson (School of Management and Labor Relations), along with Ameri and Terri Kurtzberg (Rutgers Business School), are studying the potential impact of the technology and how employers might react.

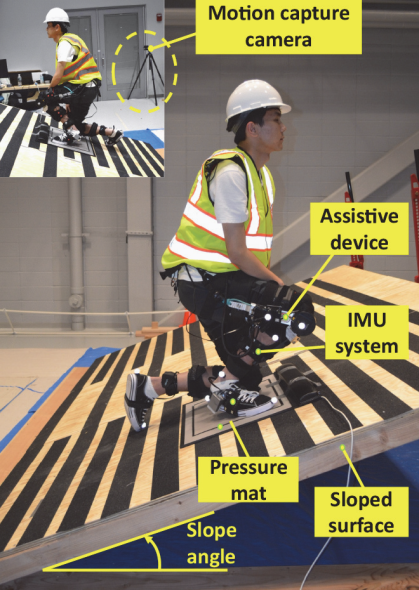

In another project, Rutgers researchers are using a $1.1 million NSF grant to develop a soft, safety-sensing robot exoskeleton for construction workers.

Powered by machine learning and mixed reality technology, the exoskeleton helps workers with strength, balance, and injury prevention when they are squatting, kneeling, or bending to perform tasks. This could improve safety for roofers and other workers in construction scenarios that involve elevated or inclined surfaces, ramps, or stairs.

Engineers Jingang Yi and Jie Gong (School of Engineering) are developing the device, while Helen Liu and Yana Rodgers (School of Management and Labor Relations) are studying how it could affect the workforce.

“We hope that this tech solution will help to reduce workplace injuries,” said Liu, an associate professor in the School of Management and Labor Relations. “In addition, the performance-enhancing benefits will enable more women and older workers to join the construction trades.”

That could alleviate a shortage of skilled workers in the industry and create better-paying career pathways for women without a college degree, Liu said.

Both projects are funded through the NSF’s Future of Work initiative.